Claw Care Stands

First-class and handmade - hydraulic, electric and mechanical hoof trimming crushes.

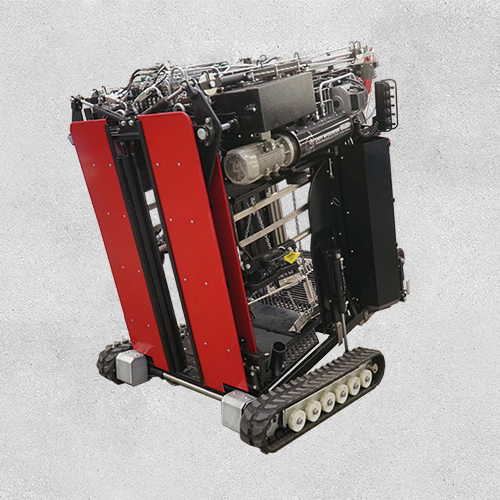

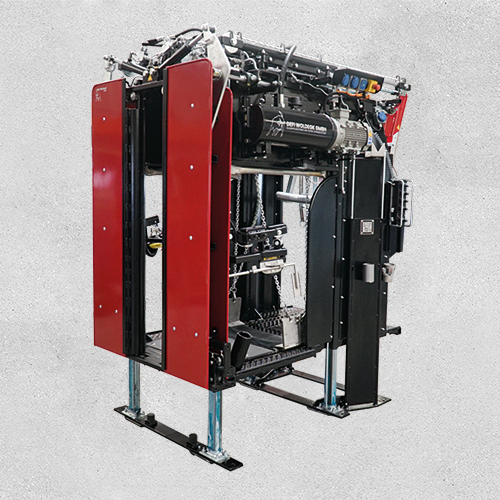

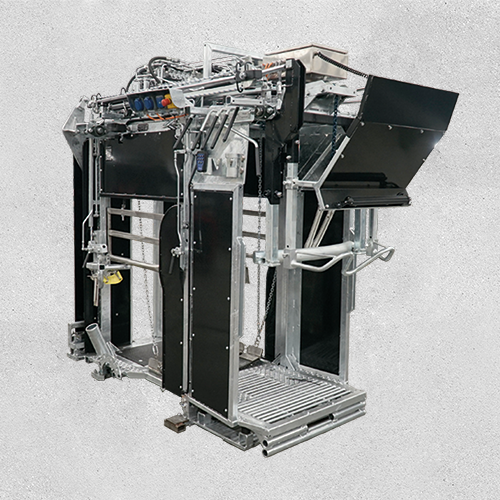

Claw care stand HY600RT

- Hydraulic with PLC control

- Tracked undercarriage with load compensation

- Stepless height adjustment

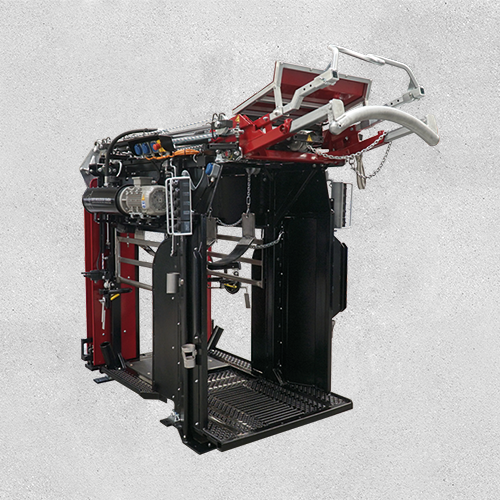

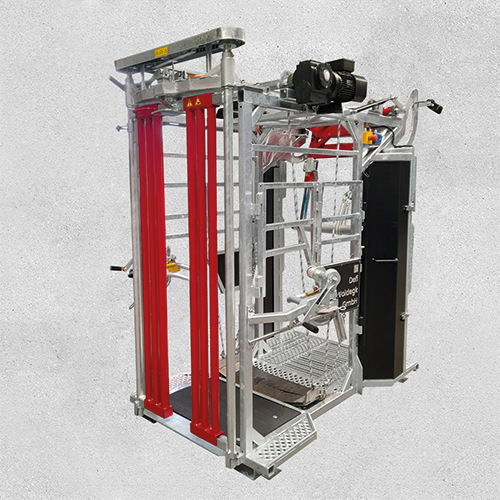

Claw care stand EL200

- Electrical operation

- Electric front and rear foot

- Chest and abdominal belt electric

- No height adjustment

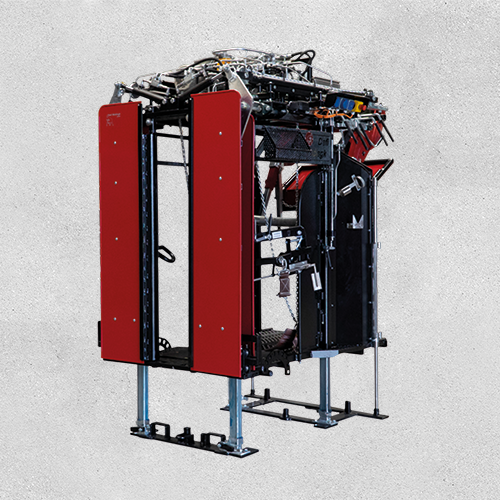

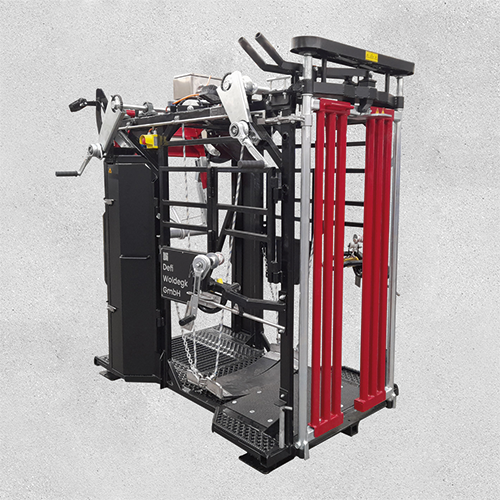

Claw care stand EL100

- Electrical operation

- Rear foot pickup electric

- Chest and abdominal belt electric

- No height adjustment

FAQ

Do you have a question?

We have the answer!

Which hoof trimming crushes does Defi Woldegk GmbH offer?

We are a company that specializes in the development and manufacture of hoof trimming crushes. We offer different types of hoof trimming crushes, including mechanical, electric and hydraulic models, to meet the different needs and preferences of farmers, hoof trimmers and animal caretakers.

What is the difference between the HY400 and HY600 models?

The HY400 hoof trimming crushes from Defi Woldegk GmbH are controlled by VPS hydraulics, which are operated using control levers. In contrast, the more advanced HY600 models have an SP control system (programmable logic controller), which enables silent operation and smooth, precise control using joysticks.

Where are the hoof trimming crushes manufactured?

Defi Woldegk GmbH hoof trimming crushes are developed and manufactured by hand at the company headquarters in the windmill town of Woldegk in Germany. Thanks to the close contact between our employees and the hoof trimmers within the group of companies, we are able to take the needs of humans and animals into account in the best possible way. Our hoof trimming crushes meet the highest quality, safety and animal welfare requirements.